Shanghai MSD PVC Flex Banner for High-Impact Displays

Advertising media, outdoor signage, and display systems rely on coated textile materials that deliver durability, consistent print quality, and long-term stability, which is why many manufacturers place significant emphasis on PVC Flex Banner when designing reliable visual communication solutions for commercial environments. Companies like Shanghai MSD continue advancing coating and lamination technologies to ensure the banners maintain visual clarity, surface uniformity, and stable physical performance across various installation conditions.

The structural foundation of flexible banner materials begins with the base fabric, commonly a polyester woven or knitted layer that provides all directional strength. The density, yarn structure, and weaving pattern determine tearing behavior, tensile stability, and resistance to deformation under tension. This textile substrate is then combined with polyvinyl chloride coatings that encapsulate the fibers, enabling seamless printing and environmental protection. Manufacturers carefully engineer the coating formulation to achieve optimal softness, flexibility, and visual smoothness to support different printing methods used in outdoor advertising.

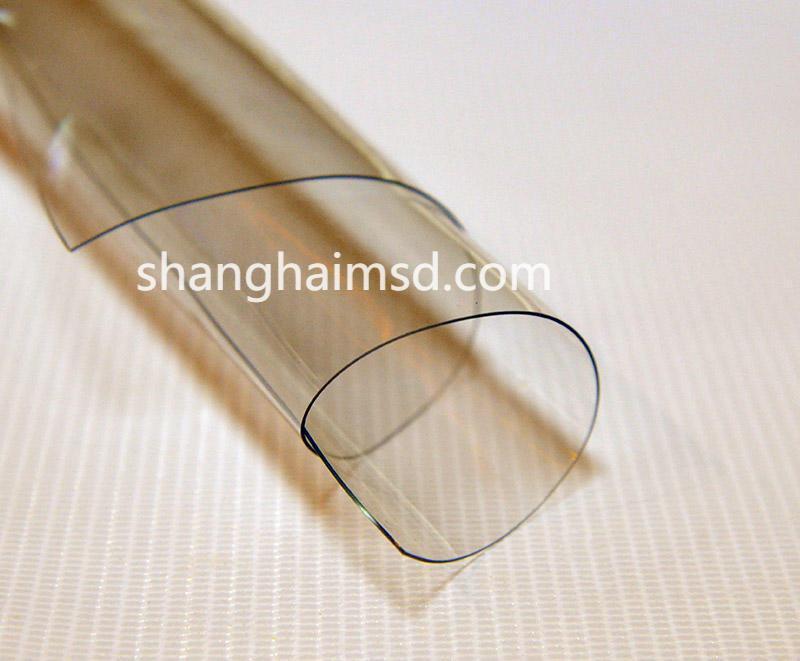

Understanding the coating process is essential to appreciating the material’s performance. Knife-coating and calendaring represent two common techniques used in production. Knife-coating allows precise thickness control by spreading PVC paste over the textile surface. This results in enhanced print receptivity and consistent optical properties. Calendaring, on the other hand, presses a molten PVC layer onto the fabric using heated rollers, producing a smooth and uniform surface with elevated strength. Shanghai MSD applies both methods depending on the expected application environment, ensuring the materials remain suitable for high-resolution digital printing, solvent-based inks, and UV-curable systems.

Another important category involves laminated banners, where two PVC layers are bonded with a reinforcing mesh in the middle. This three-layer architecture delivers improved dimensional stability while keeping overall weight manageable for large-format displays. The lamination adhesives must be engineered to resist environmental stressors such as heat expansion, cold contraction, and constant wind pressure. By adjusting bonding temperature and layer thickness, manufacturers fine-tune the flexibility and mechanical properties needed for indoor and outdoor installations.

Performance characteristics of flexible banners extend beyond structural integrity. UV resistance ensures printed colors remain vivid during prolonged sun exposure. Weatherproofing additives protect the coating surface from moisture, dust, and pollutants that accumulate in outdoor environments. Flame-retardant formulations are often required for public exhibition halls, shopping centers, or enclosed spaces where safety standards are stringent. Shanghai MSD incorporates customized additive systems that improve long-term stability without affecting print quality or mechanical behavior.

The compatibility of these banners with various printing technologies represents another critical advantage. Eco-solvent, UV, and latex printing systems all require highly controlled surface tension values to ensure precise ink adhesion. Manufacturers test the surface energy of the coating to guarantee sharp edge definition, vivid color reproduction, and minimal ink absorption. The surface must also provide scratch resistance to maintain visual appeal during transportation, installation, and repeated handling.

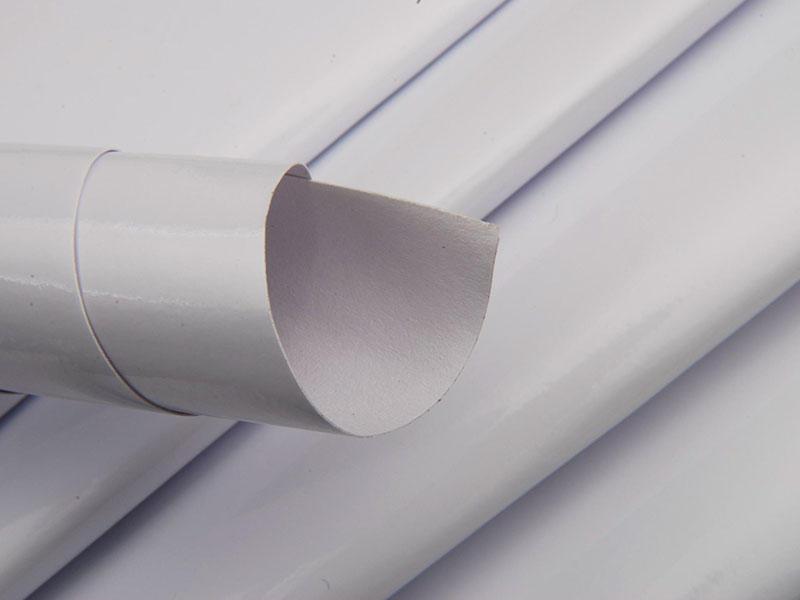

Applications for flexible banners extend across numerous commercial and public environments. Outdoor billboards benefit from the material’s wind resistance and large-format stability. Retail stores use lightweight versions for point-of-sale displays and indoor promotional signage. Event organizers favor these banners for stage backdrops, exhibition panels, and temporary structures due to their ease of transport and installation. Municipal authorities deploy them for street advertisements, lamp-post banners, and public communication displays. Each scenario demands specific mechanical, print, and environmental characteristics, which manufacturers address by adjusting reinforcement density, coating structure, and weight categories.

Additional functional enhancements further expand the banner’s versatility. Blockout banners include an opaque layer preventing light transmission, enabling double-sided printing without image interference. Backlit banners diffuse light uniformly, making them suitable for illuminated display boxes and night-time advertising. Mesh banners, constructed with micro-perforated surfaces, improve wind permeability for high-elevation or scaffold-mounted installations. Shanghai MSD provides multiple specialized product lines that support these advanced functions, meeting the requirements of advertisers, printers, and installation teams worldwide.

Industrial users often request customized properties such as anti-fungal coatings for humid regions, anti-static treatments for indoor digital signage, and cold-crack resistance for winter climates. These additions ensure that the banners remain dependable across diverse operational conditions. Manufacturers evaluate each variation through mechanical testing, colorfastness assessments, and environmental aging simulations to validate long-term stability.

For businesses, print shops, and advertising companies seeking versatile, durable, and visually consistent banner materials, the range of flexible coated fabrics available today provides a dependable foundation for both short-term campaigns and long-term installations. More information about product categories and related materials offered by Shanghai MSD is available at:

https://www.shanghaimsd.com/product/ .